Spin Testing Services

In recent years, the demand for quality and safety has become even greater with the increasing speeds in rotating products. Therefore, spin tests to verify durability and burst spin speeds are required during the development or manufacturing phases.

In recent years, the demand for quality and safety has become even greater with the increasing speeds in rotating products. Therefore, spin tests to verify durability and burst spin speeds are required during the development or manufacturing phases.Nagahama Seisakusho offers proposals of specifications and implementation on spin testing for customers’ newly developed products, as well as high-precision measurement of shapes. We can also design and manufacture attachments in addition to analyzing the product shape to achieve the target speed.

Furthermore, we can provide a consistent service from balancing to spin testing.

Optimal balancing, enabled only by a specialized manufacturer, thoroughly reduces initial unbalance and eliminates unknown factors through highly reliable spin tests.

We offer optimal balancing which enables thoroughly reduced initial unbalance and elimination of unknown factors through highly reliable spin tests.

Machine Specifications

- Type: SCHENCK spin tester Centrio100 SL

Two types of gearboxes with different rotation speeds and load capacities are available (PL12 / PL4)

Full automation of the test process with CAST 2 (Computer-Aided Spin Testing) software for spin testing

Supports measurement of up to 64 analog and digital signals

Rotor overall length: max. 820 mm

Maximum rotor speed and load

| Max. speed | Max. load | |

|---|---|---|

| Gearbox PL12 | 63,000rpm | Solid 400kg, Hollow 200kg |

| Gearbox PL4 | 240,000rpm | 10kg |

* Please contact us for rotors not listed above.

Spin test

Overspeed test: Strength evaluationHeat cycle test: Thermal fatigue evaluation

Endurance test: Fatigue strength evaluation by repeated rotation speed profile

Low Cycle Fatigue (LCF) Test: S-N curve generation and creep property evaluation

High Cycle Fatigue (HCF) Test: Fatigue evaluation under operating conditions

Centrifugal tension test: Material strengthening (acceleration to yield point)

Burst test: Evaluation of fracture conditions

Options

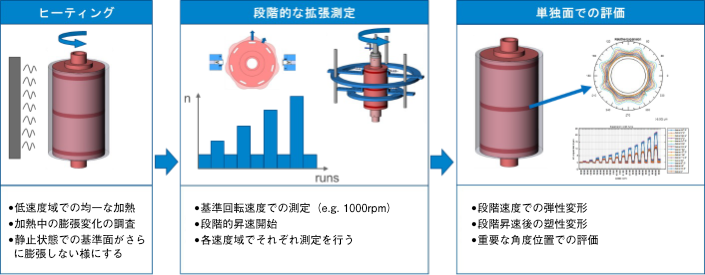

Heating: up to 250°C

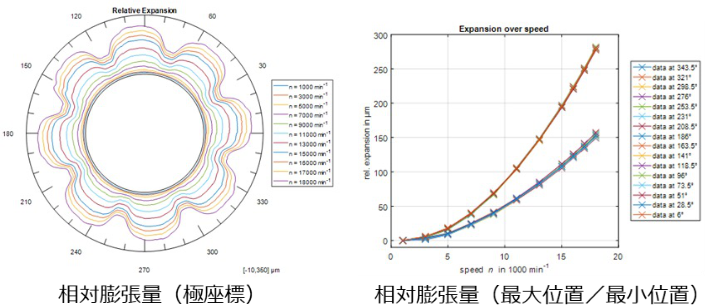

Heating: up to 250°CNon-contact real-time expansion measurement (elastic and plastic deformation, max. 3 cross sections)

Balancing evaluation before and after testing

Precise dimensional measurement before and after testing

Carl Zeiss 3D Measuring Machine ACCURA

Typical measurement accuracy: 1.2+L/350μm, where L is the measurement length

High-speed video recording during bursts (video rental available according to test contents)

Example of spin testing for EV motor

Example of non-contact real-time expansion measurement output

Reference Results(Spin test system, made by SCHENCK Rotec)

Spin test system, made by SCHENCK RotecEV motors

Hyperloop rotating parts

Aircraft jet engines

Turbo machinery

Rocket pump parts

SCHENCK spin testers available for sale(Machine Specification)

| centrio | Weight,max | Diameter,max | Length,max | Speed,max | Drive power,max |

| size | kg | mm | mm | rpm | kW |

| 20 | 10 | 200 | 250 | 3,000- 240,000 |

15 |

| 50 | 50 | 500 | 315-615 | 30 | |

| 70 | 400 | 700 | 650 | 75 | |

| 100 | 800 | 1,000 | 820 | 90 | |

| 150 | 1,600 | 1,500 | 1,000-1,200 | 160 | |

| 200 | 3,150 | 2,000 | 1,250-2,000 | 250 | |

| 270 | 6,300 | 2,700 | 1,250-2,250 | 315 |