Crankshaft

Crankshaft

Recently engine mass production requires flexible production system for changing products frequently.

221LAMC is crankshaft balancing machine for passenger cars which is developed for flexible production line.

221 LAMC can automatically measure, correct and inspect, nevertheless it has minimized footprint.

Minimized footprint achieves the flexibility of the layout design at the production line.

221LAMC is crankshaft balancing machine for passenger cars which is developed for flexible production line.

221 LAMC can automatically measure, correct and inspect, nevertheless it has minimized footprint.

Minimized footprint achieves the flexibility of the layout design at the production line.

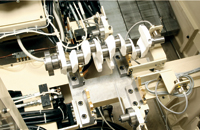

- Measuring Station

- The crankshaft is transferred by inboard loader. On the measuring station, crankshaft is driven by hard coated friction roller drive system. Crankshaft of in-line three-cylinder engine is measured unbalance by supported at #1 and #4 journal, and in-line four-cylinder crankshaft is supported at #1 and #5 journal.

- Correction station

- On the correction station, the unbalance of crankshaft is removed by NC machining. The unbalance amount is converted to drilling depth by the measuring unit.

- Inspection

- Corrected and air-blown crankshaft is inspected on the measuring station and then determined OK or NG.

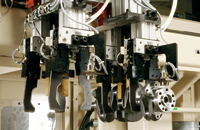

- Inboard Gantry Loader (Twin Manipulators)

- Inboard Gantry Loader (Twin Manipulators)

The crankshaft is transferred between each station by inboard gantry loader.

Adopting twin manipulators makes rapid inboard transfer.

- Micro Processor Measuring Unit MMi-902C

- Micro Processor Measuring Unit MMi-902C

This is consisted measuring unit and panel computer with TFT panel.

Setting of MMi-902C is available by touch panel operation. MMi-902C can be maintained easily, since it has self-diagnostics function and module system.